Plastic manufacturing has revolutionized modern industry and become an essential component in the production of various consumer goods. However, the process of plastic manufacturing has undergone significant changes over the years. One of the most significant changes in the manufacturing process is the introduction of parallel twin screw barrels.

Parallel twin screw barrels are an essential component in the plastic manufacturing process. They are used to mix, melt, and extrude plastic materials. These barrels have revolutionized the plastic manufacturing industry by providing a more efficient and effective way of processing plastic materials.

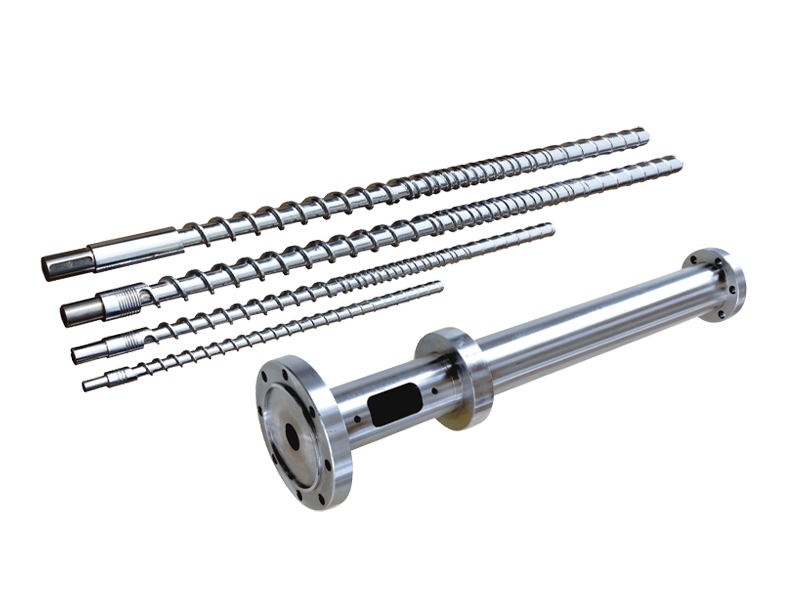

The parallel twin screw barrel is a unique design that incorporates two screws that rotate in opposite directions inside a barrel. This design creates a more efficient way of mixing and melting plastic materials. The parallel twin screw barrel has several advantages over the conventional single screw barrel.

One of the significant advantages of the parallel twin screw barrel is its ability to process a wide range of plastic materials. This barrel can handle a range of plastic materials, including thermoplastics, elastomers, and engineering resins. This versatility makes the parallel twin screw barrel an excellent choice for manufacturers who need to process multiple plastic materials.

Another advantage of the parallel twin screw barrel is its ability to produce high-quality products. The mixing and melting process is more consistent and precise, resulting in a more uniform product. This consistency is essential for manufacturers who require a high-quality product.

The parallel twin screw barrel also has a higher throughput than the conventional single screw barrel. This means that manufacturers can process more plastic materials in a shorter amount of time, increasing their productivity and efficiency. This increased throughput also leads to a reduction in manufacturing costs, making the parallel twin screw barrel a more cost-effective solution.

In addition to its efficiency and cost-effectiveness, the parallel twin screw barrel is also more environmentally friendly. The design of the barrel reduces waste by minimizing the amount of plastic materials that are lost during the manufacturing process. This reduction in waste is not only good for the environment, but it also saves manufacturers money in the long run.

The parallel twin screw barrel has revolutionized the plastic manufacturing industry by providing a more efficient and effective way of processing plastic materials. Its ability to process a wide range of plastic materials, produce high-quality products, increase throughput, and reduce waste has made it an essential component in the plastic manufacturing process.

In conclusion, if you want to revolutionize your plastic manufacturing process, you should consider using a parallel twin screw barrel. Its unique design, versatility, high-quality product output, increased throughput, and environmentally friendly features make it an excellent choice for any manufacturer.

Cable made of HDPE, PVC, LDPE, XLPE, LSHF, TPU, LSOH, LSLH, Fluoroplastic teflon (high-temperature) and Silicone rubber insulation material

Widely used for electronic wire, special cable, power line, building wire, insulating sheath, telephone wire, military product, audio line, network cable, power cable, blank pipe, copper cable lock rope and automobile cable, etc.

EN

EN  简体中文

简体中文