Extrusion is a widely used manufacturing process in various industries, including plastics, rubber, and food processing. It involves pushing a material through a die to create a continuous profile with a desired cross-section. The efficiency and quality of extrusion greatly depend on the performance of the screw barrel, which is the heart of the extruder. In recent years, bimetallic screw barrels have gained significant popularity due to their numerous advantages over traditional options. Let's delve into the benefits of bimetallic screw barrels in extrusion.

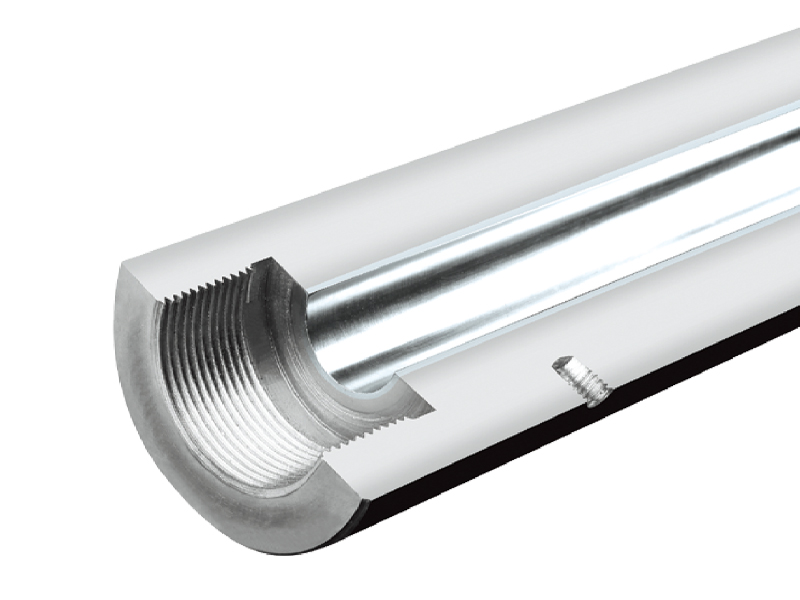

Firstly, bimetallic screw barrels are renowned for their exceptional durability. These barrels are constructed with two distinct materials: a tough and wear-resistant alloy on the inside, known as the "lining," and a high-strength steel as the outer "body." The combination of these materials provides superior resistance to abrasion, corrosion, and heat. As a result, bimetallic screw barrels have a significantly longer lifespan compared to their conventional counterparts, reducing downtime and maintenance costs.

Another significant advantage of bimetallic screw barrels is their enhanced processing capabilities. The wear-resistant alloy lining on the inside of the barrel allows for precise control of melt temperatures during extrusion. This improved temperature control leads to better melt homogeneity and higher quality end products. Furthermore, the high-strength steel body provides excellent resistance to deformation and can withstand higher extrusion pressures. This enables the extruder to process a wider range of materials, including those with higher viscosity and temperature requirements.

Bimetallic screw barrels also offer remarkable flexibility in terms of customization. The wear-resistant alloy lining can be tailored to meet the specific requirements of different materials and applications. For instance, materials with high filler content or abrasive additives can cause significant wear on conventional screw barrels. However, bimetallic barrels can be engineered with a wear-resistant lining specifically designed to handle such challenging materials, ensuring extended service life and consistent performance.

Moreover, the bimetallic construction of these screw barrels allows for cost-effective maintenance. When wear occurs, instead of replacing the entire barrel, only the lining needs to be replaced. This reduces downtime and saves on replacement costs. Additionally, the wear-resistant alloy lining can be easily repaired or rebuilt, further extending the life of the barrel and optimizing production efficiency.

In terms of energy efficiency, bimetallic screw barrels can contribute to significant savings. The precise temperature control provided by the wear-resistant alloy lining minimizes energy consumption by reducing the need for excessive heating or cooling. Additionally, the improved melt quality achieved with bimetallic barrels reduces the occurrence of defects, resulting in less material waste and increased overall productivity.

Lastly, bimetallic screw barrels offer compatibility with various extrusion processes and machinery. Whether it's a single-screw or twin-screw extruder, bimetallic barrels can be seamlessly integrated into the existing equipment, allowing manufacturers to upgrade their extrusion lines without extensive modifications. This adaptability makes bimetallic screw barrels a cost-effective solution for improving the performance of both new and existing extrusion systems.

In conclusion, the advantages of bimetallic screw barrels in extrusion are evident. Their exceptional durability, enhanced processing capabilities, customization options, cost-effective maintenance, energy efficiency, and compatibility make them an attractive choice for manufacturers across different industries. By investing in bimetallic screw barrels, companies can achieve higher productivity, superior product quality, and cost savings in the long run.

Application: all kinds of vertical and horizontal injection machines, extrusionmachines, injection machine, bakelite machine, rubber tube, blownfilm machine, etc.

Processing range: Dual alloy screw: diameter: Φ15mm -Φ360mm;Effective length: 10000mm

Dual alloy material tube: inner diameter 14mm -Φ200mm;Effective length: 6000mmSkin membrane density: 98-99.8%Hardness: Hv1100-1400℃Sticky strength: more than 10000Psi

Bimetallic barrel material: 38CrMoAlA、40Cr、42CrMo

Bimetallic screw material: 38CrMoAlA、31CrMoV9(foreign)

Screw / Barrel alloy powder (iron / nickel base):

GK - A: special-purpose alloy

GK - B: high wear resistance, high corrosion resistance, good

toughness, good crack resistance

GK - C: high wear resistance, high corrosion resistance

GK - D: high wear resistance

Field of application:suitable for LCP, PA + GF, PET + GF, PBT + GF, PC + GF all kinds of plasticadditives such as glass fiber, fire-proof agent, carbon powder and PPA, PPO,LCP, magnetic powder, special engineering plastics, such as PC.

EN

EN  简体中文

简体中文